SciTech Tuesday: Bakelite

One of the first plastics to be produced entirely in the lab from synthetic components, Bakelite was unique because of its electrical resistance and heat-proof qualities. Because it could be molded very quickly, it was ideal for mass production where large numbers of identical units could be made one after another. Bakelite quickly became incorporated into the non-conducting parts of electronics and automobiles including radios, light bulb bases, insulators, and automobile distributor caps. Following the war, factories transitioned to producing a variety of products for civilian use including kitchenware and novelty jewelry, popular today with collectors.

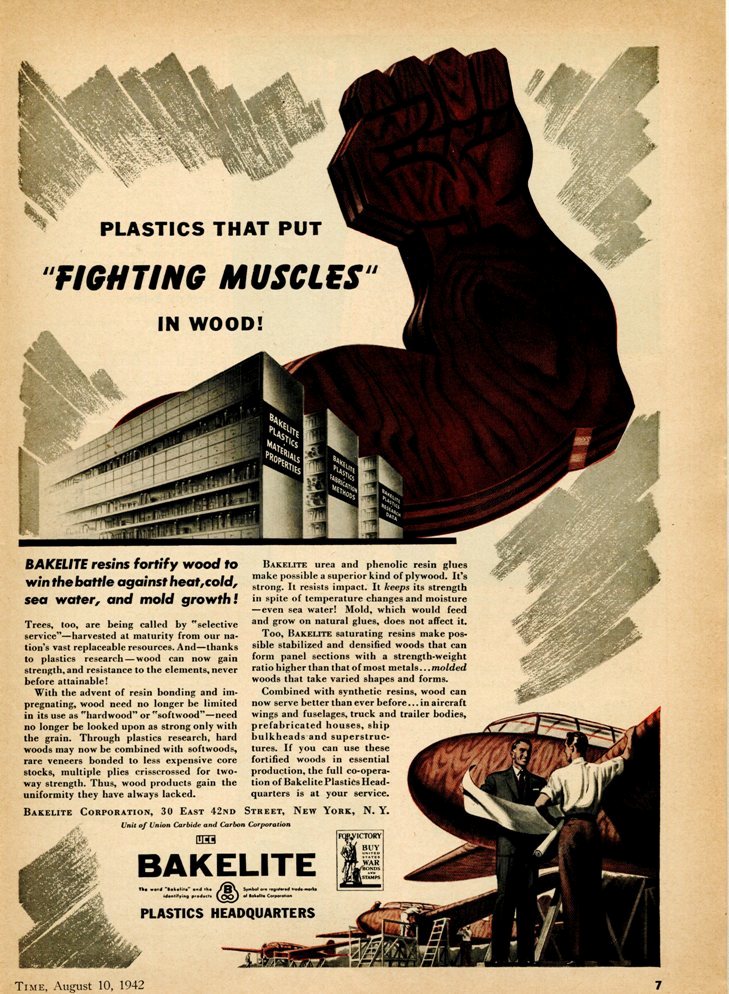

Bakelite is made from phenol and formaldehyde. By adding wood flour under high pressure, it becomes strong and extremely resistant to melting. Bakelite’s strength and durability come from its chemical structure as a polymer, a large molecule made up of repeating units. Because of its toughness, Bakelite was even considered by the Mint as a potential replacement for copper pennies before settling on galvanized steel. The August 10, 1942 issue of Time featured this advertisement, touting benefits of Bakelite saturated wood for use in aircraft, automobile, and ship production.

Post by Annie Tête, STEM Education Coordinator

Leave a Reply